2024 Team Organization Chart

Mechanical Team

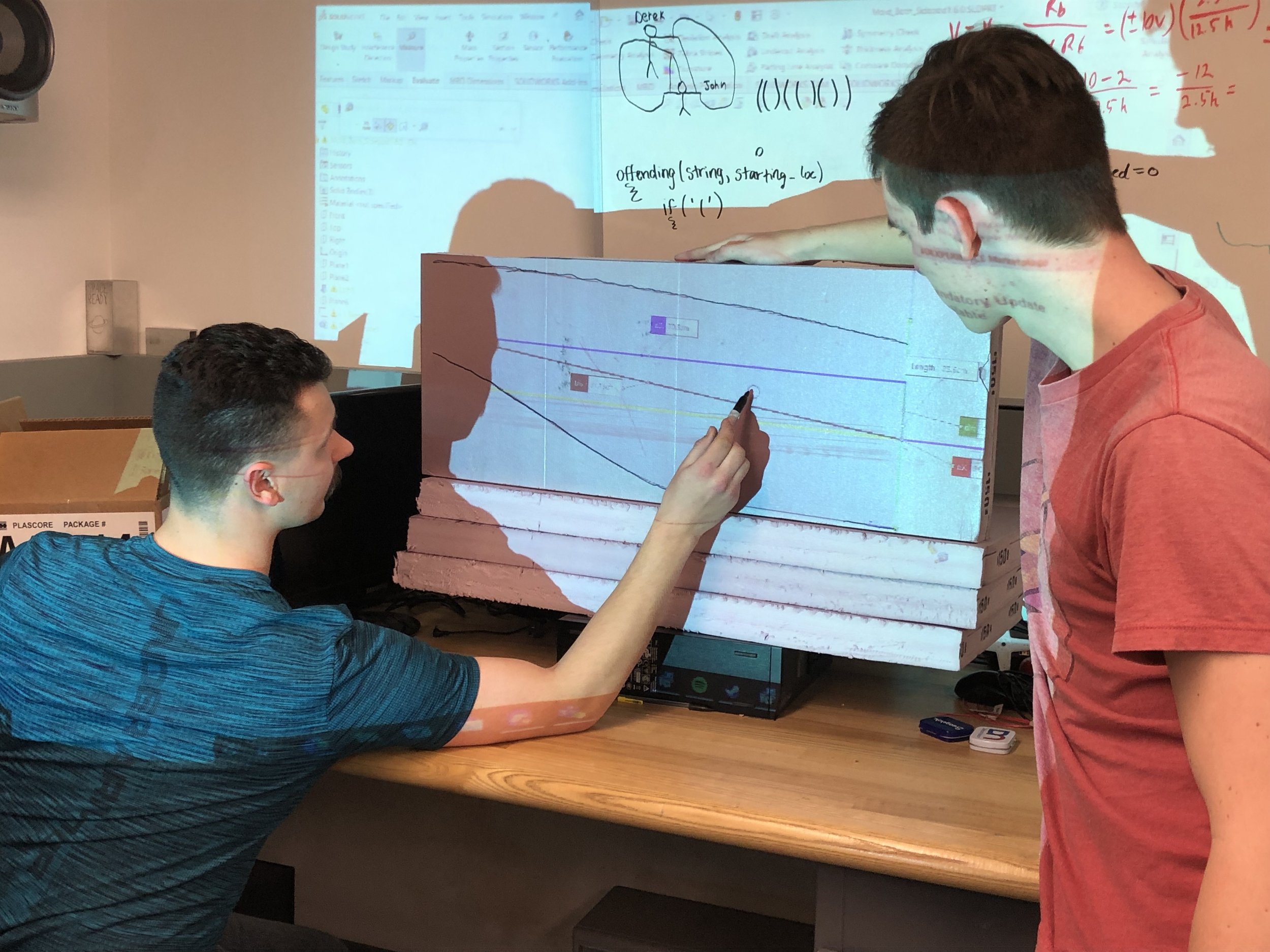

Vehicle Dynamics

The Vehicle Dynamics team focuses on optimizing the performance of the racing car under all dynamic events. They deal with factors such as grip, stability, balance, and control, aiming to understand and improve how the car behaves.

This team builds advanced simulation tools and uses real-world testing data to model the car's behavior, predict its performance, and propose adjustments to enhance its drivability.

Additionally, the VD team also oversees actual testing of the vehicle, setting up the car, creating test plans, and organizing test days.

This team is a great fit for students interested in data-driven optimization of systems, building models and simulations to predict performance, while also getting the opportunity for hands-on work with the vehicle.

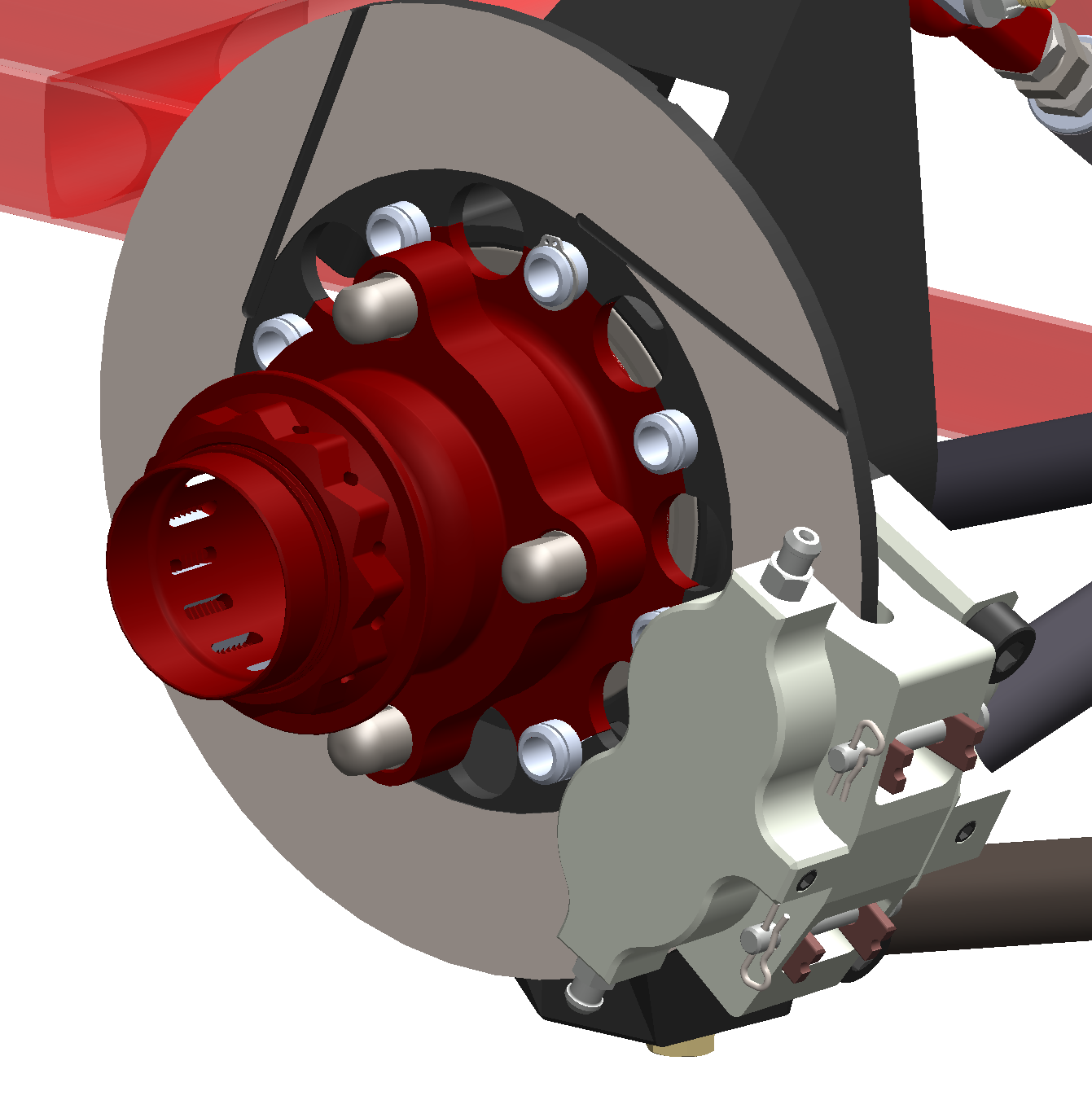

Brakes

The Brakes team is responsible for designing, fabricating, and testing a reliable and efficient braking system. This ensures that the car can decelerate rapidly, maintain stability under braking, and meet the specific brake lock requirements of the FSAE competition.

Their work involves selecting suitable materials for the brake discs and pads, designing the hydraulic system, and calculating the optimal brake bias to balance the braking forces between the front and rear wheels. They use performance simulations and real-world tests to validate their designs and adjustments.

Aerodynamics

The Aerodynamics team focuses on enhancing the performance of the car by optimizing its shape to reduce air resistance and maximize downforce. This includes designing components like the front wing, rear wing, undertray, and side wings. Each element is meticulously crafted using Computational Fluid Dynamics (CFD) software to simulate air flow and pressure distribution, aiding in the prediction and improvement of the vehicle's aerodynamic performance.

The team must balance the trade-off between increasing downforce, which improves traction and cornering speeds, and minimizing drag, which increases top speed and energy efficiency. Their work also involves close coordination with other sub-teams to ensure manufacturability and seamless integration with other subsystems.

Ergonomics

The Ergonomics Team on a Formula SAE (FSAE) team is responsible for ensuring that the racing car is comfortable, safe, and easy for the driver to operate. This includes designing and arranging components such as the seat, pedals, steering system, harness, and controls to suit the driver's physical characteristics and driving position. They use human factors engineering and anthropometric data to create a cockpit layout that optimizes driver performance and minimizes fatigue.

This is a great team for students to join if they want to work on a wide variety of smaller, more diverse projects.

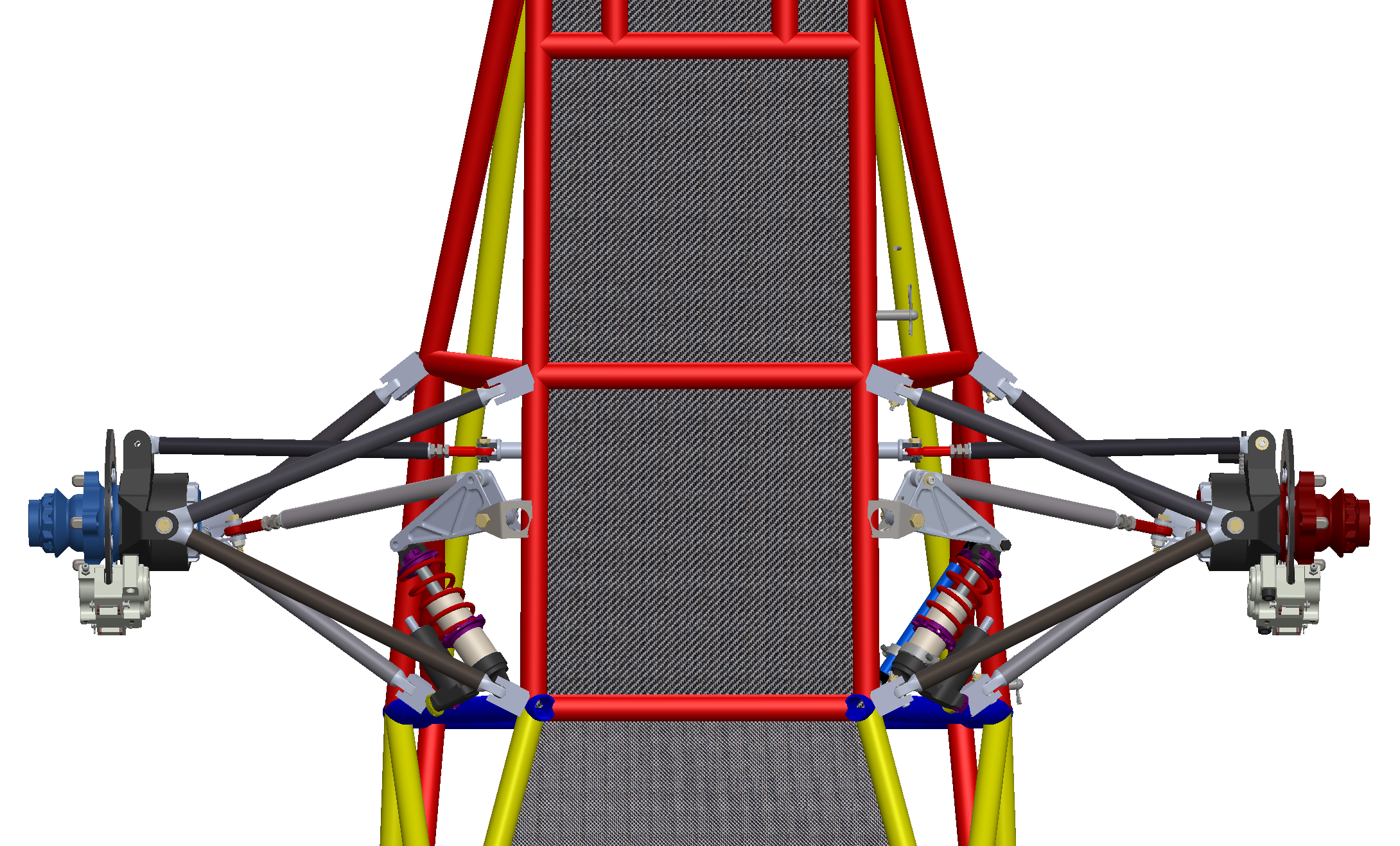

Suspension

The Suspension team is responsible for designing and constructing the vehicle's suspension system, a critical element that influences handling, stability, and cornering performance. They work to optimize parameters like wheel alignment, spring rates, and damping to provide the best possible grip and vehicle dynamics. Adherence to various rules and load conditions, along with seamless integration with the chassis and wheel assembly, is also a crucial part of their role.

The suspension team is perfect for individuals interested in gaining experience in part and component design, while also being exposed to vehicle dynamics principles.

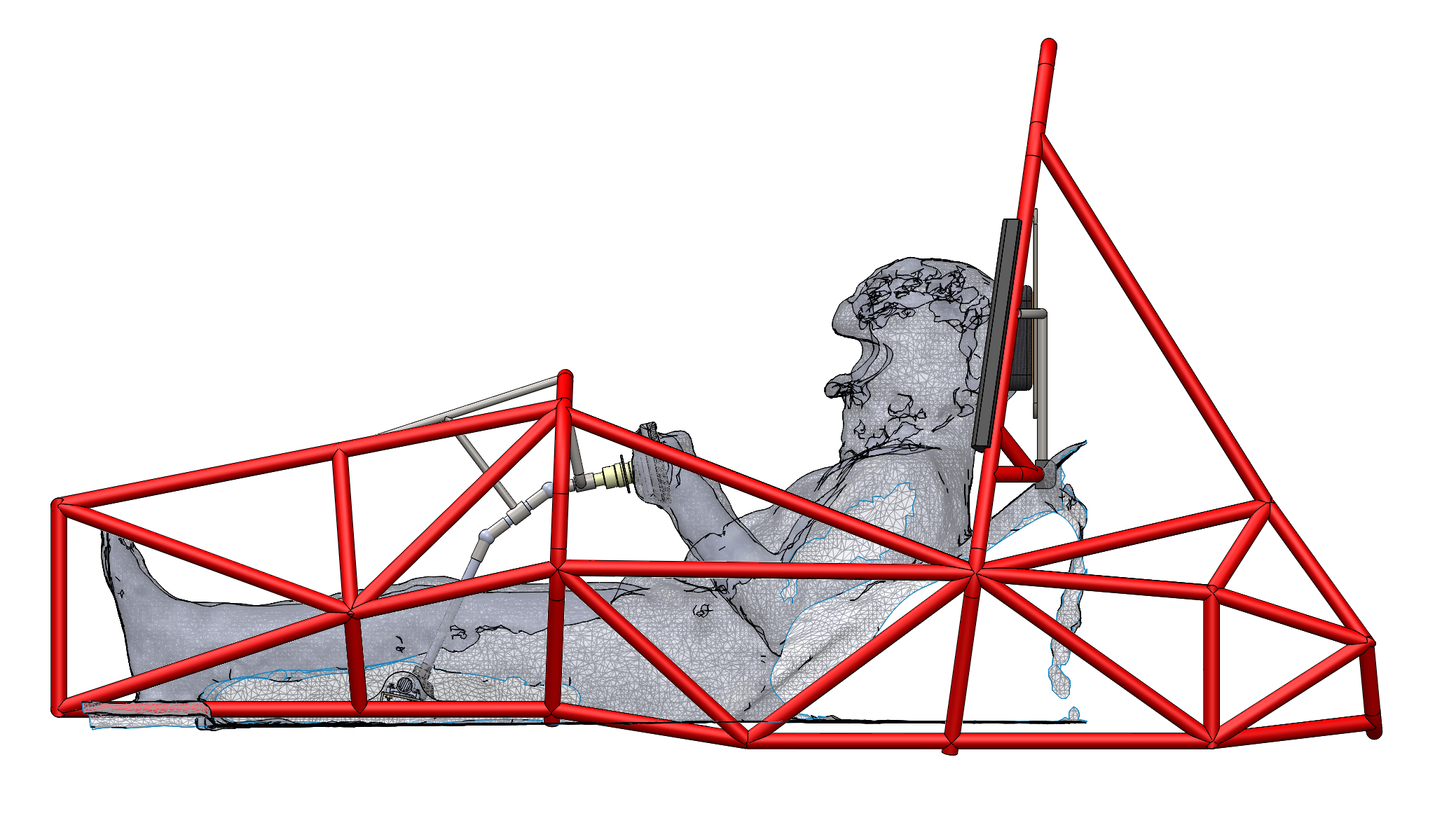

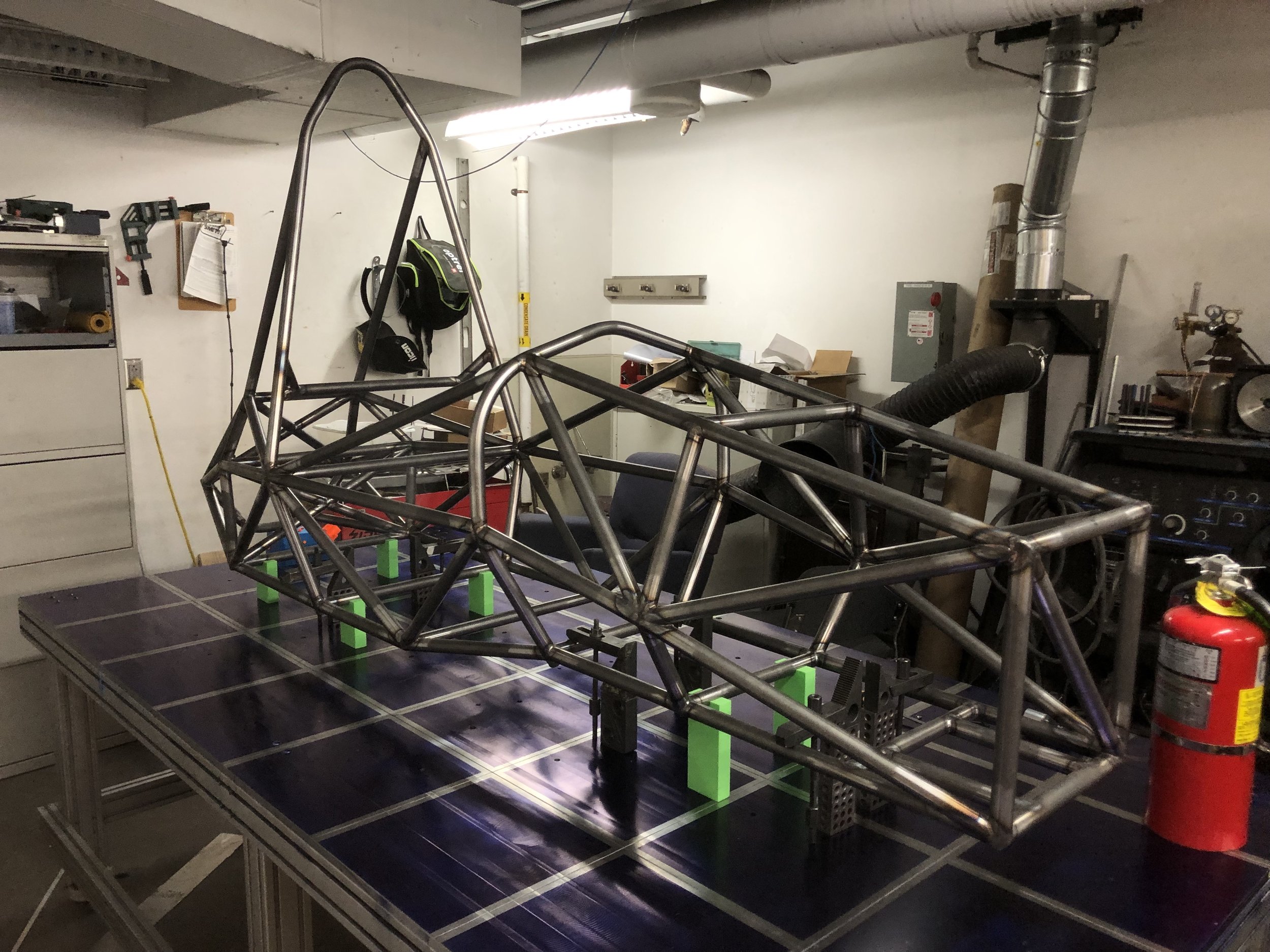

CHassis

The Chassis team designs and builds the core structure of the racing car, ensuring it is both lightweight for speed, stiff for performance, and rules legal for safety. They employ software simulations and engineering principles for optimal structural rigidity, weight distribution, and driver ergonomics. The team also ensures strict adherence to safety regulations while integrating components from other sub-teams.

Powertrain

The Powertrain team is dedicated to designing and developing the mechanical aspects of the electric powertrain system. Their primary focus is determining powertrain performance requirements to meet our dynamic event goals, and design of drivetrain components from motor to the tire. Their goal is to provide a reliable, efficient, and low-mass solution.

Composites

The composites team manufactured fiber-reinforced composites to produce extremely high performing materials for all aspects of our cars, most notable the aerodynamic elements and the body work.

The composites team is a great fit for students looking for something hands-on practical while also having an opportunity to gain CAD design experience through the design of molds, tooling, and other components. Our team members will also teach you composite-based materials science through testing and application.

Manufacturing

On this team you will organize manufacturing tasks and work with Akron’s ASEC Machine Shop and 3D printing labs to produce parts for the vehicle. You also get the opportunity to take Tooling U machine shop certification to work on CNC machines.

In our Design Center, you get the opportunity to learn TIG welding and fabrication skills to produce chassis, suspension components, jigs, and any other part we may need produced.

Being part of the manufacturing team is a great step for first-time members who want to gain hands-on experience before diving into vehicle design. You will have the opportunity to interact will all other sub-teams and participate in design reviews, discussing and promoting Design for Manufacturing(DfM) and Design for Assembly(DfA) strategies